Plasma Transfer Arc (PTA)

In 1996 Austral Technologies purchased and installed the largest Plasma Transferred Arc (PTA) system in the world. This marvel of German ingenuity is able to deposit up to 25kg/hr of Tungsten Carbide hard-facing.

In 2015, Austral Technologies installed a second fully automatic PTA system of the same capacity, and in 2024 we commissioned our third PTA system.

These PTA machines are the largest in the Southern Hemisphere which gives Austral Technologies an unmatched manufacturing capacity.

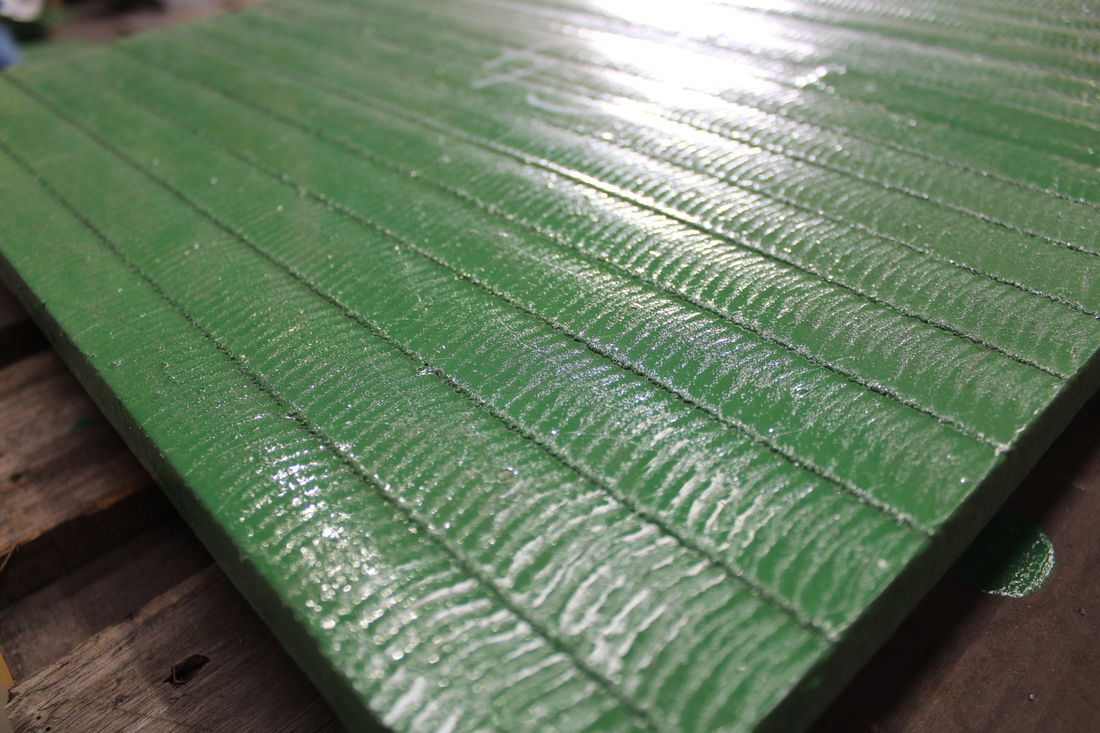

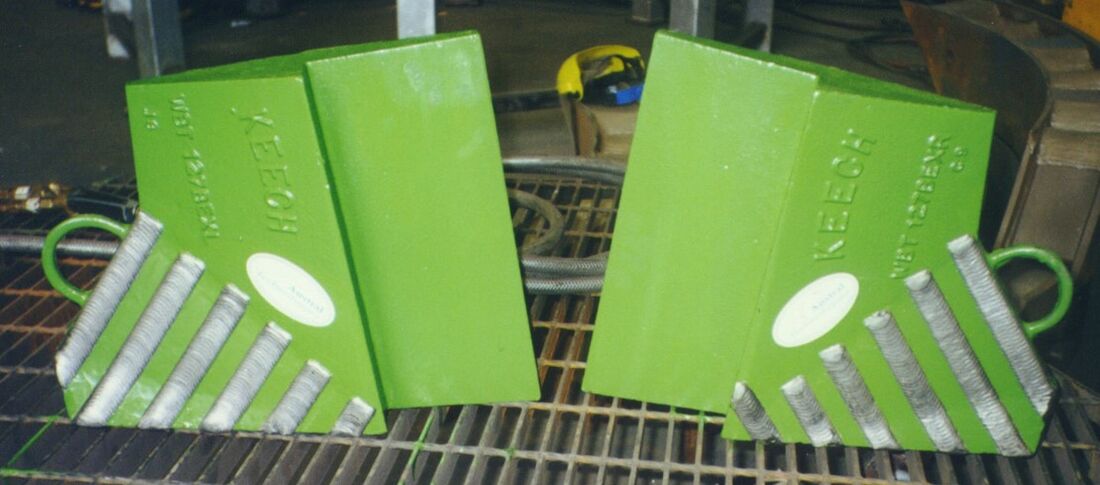

| After years of trialling and perfecting this PTA machine, the Austral Technologies Special Plasma Overlay Technology (SPOT60®) deposit was born. SPOT60® is unrivalled in abrasion resistance and used mainly in the harsh environments found in Iron Ore and Gold mining operations. Today, SPOT60® is sold all across Australia as well as overseas markets including South Africa and Chile. Using the same PTA system, Austral Technologies also created our SPOT61®, which is a variant of our SPOT60®. SPOT61® contains additional chrome and is tailored to those abrasive environments that also expose the wear components to additional corrosion. | ||||||||||||||

| SPOT60® Properties

Matrix Hardness: 58 HRC WC Hardness: 2000 HV1 |

|

|

| SPOT60® Applications Austral Technologies SPOT60® can be applied to a wide array of different applications to give you the best abrasion wear resistance profile available. Such applications include: Wear plates, ground engaging systems, mixer paddles, ore handling systems, extruders, scraper bars, choke and feeder chutes, raker bars, conveyor sideliners, sizer segments and transfer chutes. |  |

|  |  |

| The Benefits of Austral Technologies PTA. In extreme abrasive environments, the hard-facing that our PTA machine can produce is unrivalled in its toughness and durability. This technology produces a minimal weld dilution of 2-5% and also allows us to maintain control of the distribution of the tungsten carbide particles within the deposit itself. Our most widely used product using the PTA system is our SPOT60® wear plate, however, we have the ability to be able to apply this deposit almost any other wear component to significantly increase its life in abrasive wear situations. |  |