Our Products

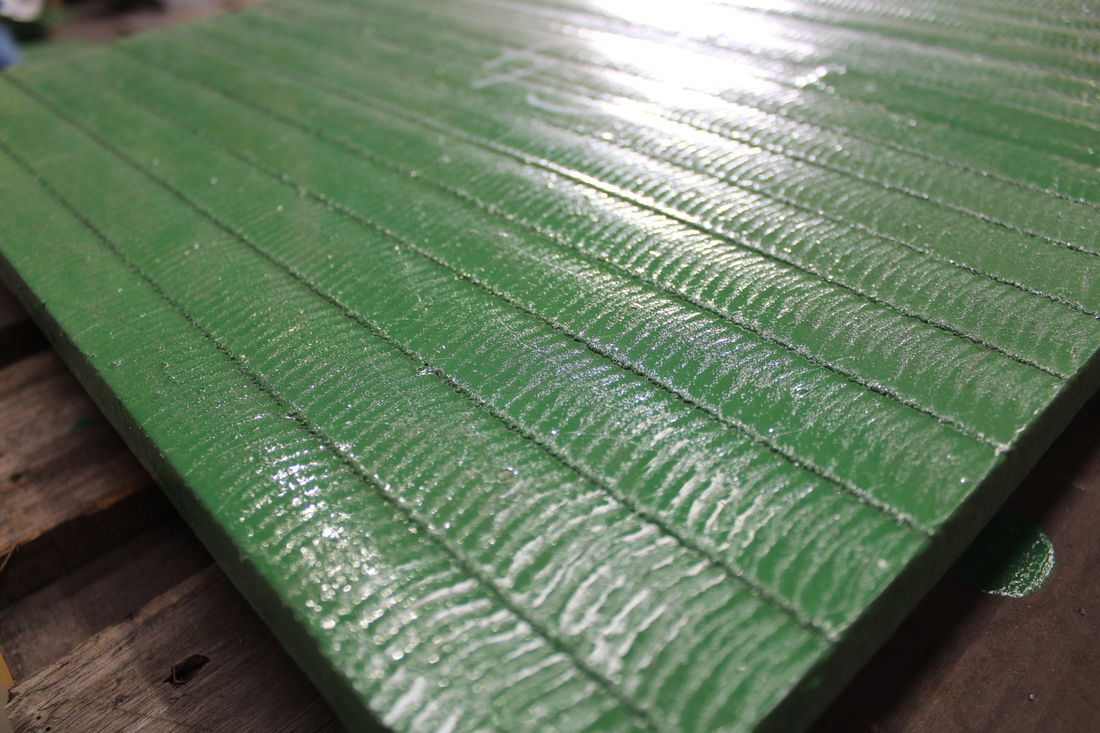

SPOT60®After years of trialling and perfecting this PTA machine, the Austral Technologies SPOT60® Wear Plate was born. SPOT60® is unrivalled in abrasion resistance and used mainly in the harsh environments found in Iron Ore and Gold mining operations. Today, SPOT60® is sold all across Australia as well as overseas markets including South Africa and Chile. SPOT60® is manufactured using the unique Implantechnik Servat 3 High Deposition PTA Welding System and has been utilised by the mining, power generation and mineral sands industries since 1998. SPOT60® performs best in sliding abrasion applications such as transfer chutes and skirt liners where the drop of material is at a maximum drop height of 3m. The most economical use of SPOT60® is obtained when it is used in high wear areas only and alongside standard wear plate products such as Chrome Carbide wear plate and Ni-Hard liners. The wear performance of SPOT60® has been tried, tested and proved many times over. Click on our SPOT60® case studies below for more information on its wear profile. Using the same PTA system, Austral Technologies also created our SPOT61®, which is a variant of our SPOT60®. SPOT61® contains 5% Chrome and is tailored to those abrasive environments that also expose the wear components to additional corrosion. |  |

Case Studies

To see how our SPOT60® has performed compared to the standard wear plates, please see the below case studies for more detailed information.

HPGR Choke Chutes | Scrubber Discharge Chute |

Plasma Transfer Arc in Action

| Patented Bimetallic Grinding ComponentsCrushing and grinding of coal and ores has traditionally been handled using components cast from wear grade irons and exotic steels and alloys, such as White Irons, NiHard, HiChrome, etc. These irons and alloys, while being wear resistant, are also quite brittle and some are unable to withstand excessive rapid temperature variations, or significant impact, etc. Austral Technologies recognized a requirement for components that are able to withstand these extreme conditions, while at the same time, provide superior wear resistance. A patented BiMetallic Grinding Component was developed in the form of a specific alloy steel base material and a wear resistant hard-face overlay. This provides a life increase over the original NiHard white iron component, while providing better impact and superior ability to withstand rapid extreme temperature fluctuations. Some of Austral's Chromium Carbide overlays have reached thicknesses of up to 160mm; these being applied to NiHard IV High Pressure Rolls Crusher Segments. |