Metal Spray Surface Coating

|  |

Metal Arc spraying (MAS) is one process in a short list of mechanically bonded surface engineering deposits. Although not a complete metallurgical bond, MAS can produce bond strengths of around 9,000 to 10,000psi. Austral Technologies offers expert metal spray surface coating services designed to enhance the performance and longevity of your equipment. Using advanced thermal spray technologies, we apply a wide range of coatings onto metal surfaces that provide superior resistance to wear, corrosion and high temperatures.

Chromium Boride deposits are regularly Metal Arc Sprayed onto components such as boiler tubes and economizer tubes for coal fired power stations to combat high temperature erosion. While Chromium Carbide or Complex Chromium Carbide deposits are can be sprayed onto components subject to fine particle erosion and thermally sprayed aluminium (TSA) is regularly sprayed onto pipes and valve bodies to protect against the elements and corrosion under insulation (CUI).

Austral Technologies utilises a variety of metal spray wires that can be chosen to best meet your needs and deliver the most effective results.

This can be done on site and in-situ as well as at our Welshpool workshop.

| Nickel Aluminium Bond Coat | |

| Bond Strength: 9,750 PSI | |

| Hardness: 55-60 Rb | |

| This Nickel Aluminium bond coat is a pre-alloy wire that produces a superior bond coat which is dense and resistant to high temperature oxidation, thermal shock and abrasion. |

| Chromium Boride | |

| Bond Strength: 6,000 PSI | |

| Hardness: 72 R | |

| This produces a hard, abrasion, erosion and corrosion resistant coating and can operate in temperatures up to 900C for extended periods. Typical applications: Fly ash fans, boiler tubes, extruders, sand mining equipment, particle abrasion and erosion at high and low temperatures. |

| Aluminium | |

| Bond Strength: 2,000 PSI | |

| Hardness: 25-30 HB | |

| Aluminium is used to provide protective coatings against atmospheric, chemical and high temperature corrosion. Aluminium is also used to produce electrically and thermally conductive coatings and to reclaim mis-machined aluminium surfaces. |

| ZnAl 8515 | |

| Bond Strength: 1,196 PSI | |

| Hardness: 15-20 HB | |

| The ZnAl 8515 is mainly used in the protection of iron and steel against corrosion. The combination of zinc and aluminium provides excellent cathodic protection in most environments. Whilst in mould manufacture, this material being harder than pure zinc gives better service life and improved thermal conductivity. It can also be used for EMI Screening and End Spraying of Capacitors. |

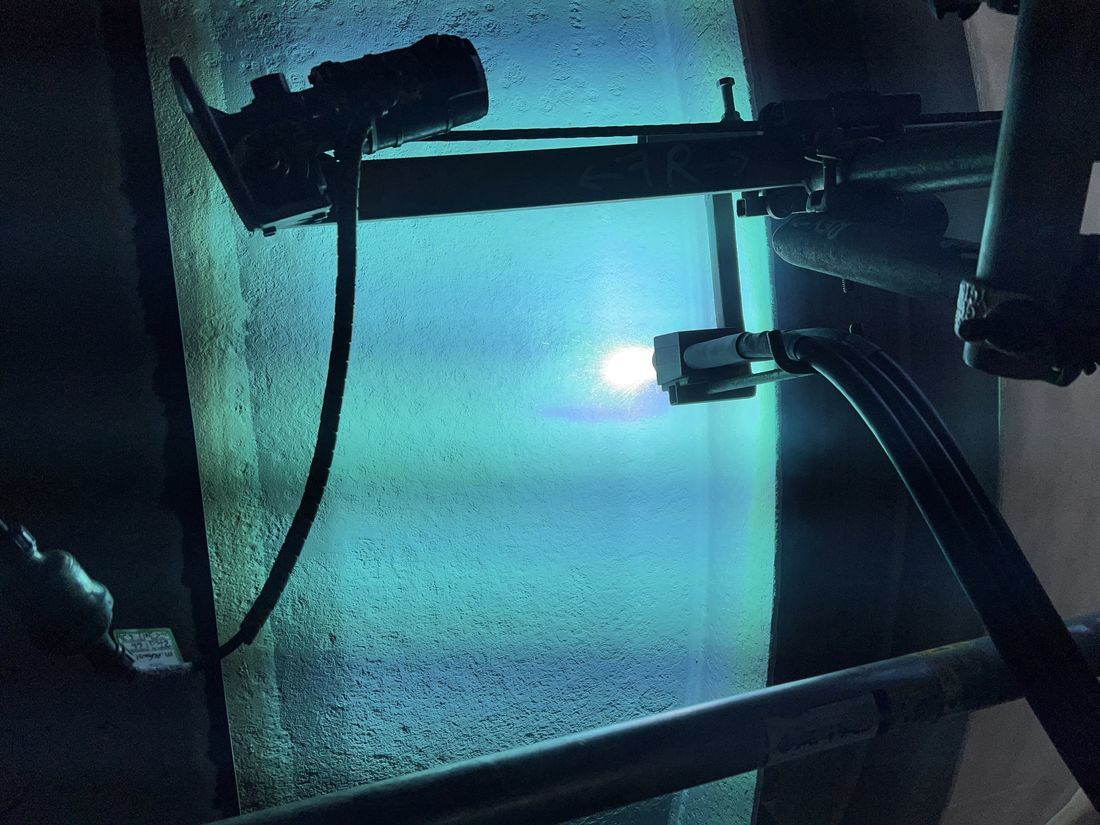

Metal Spraying in Action